Tong Manipulator Boot TKB33A

Tong Manipulator Boot TKB33A

A boot with excellent flexibility and durability

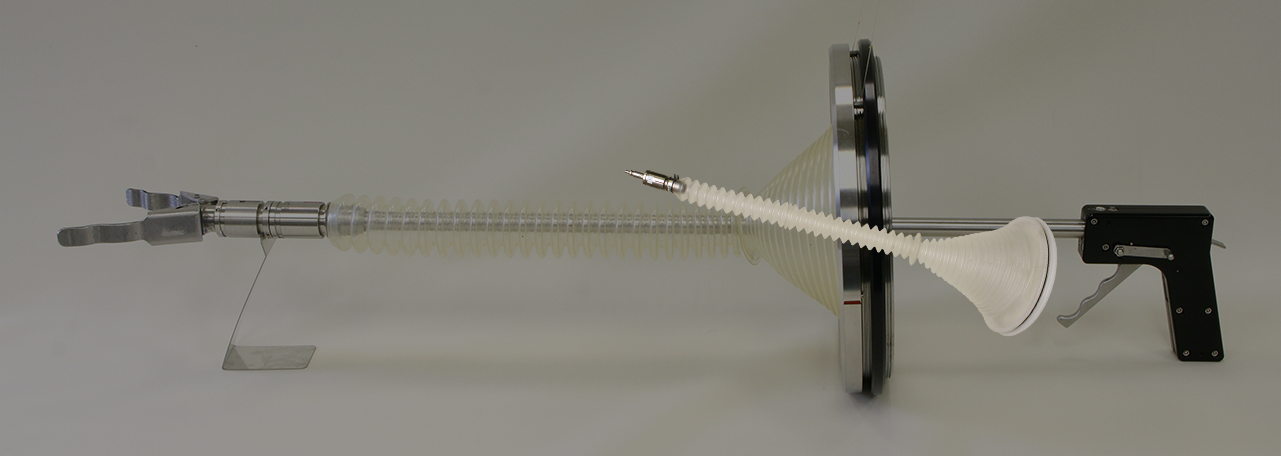

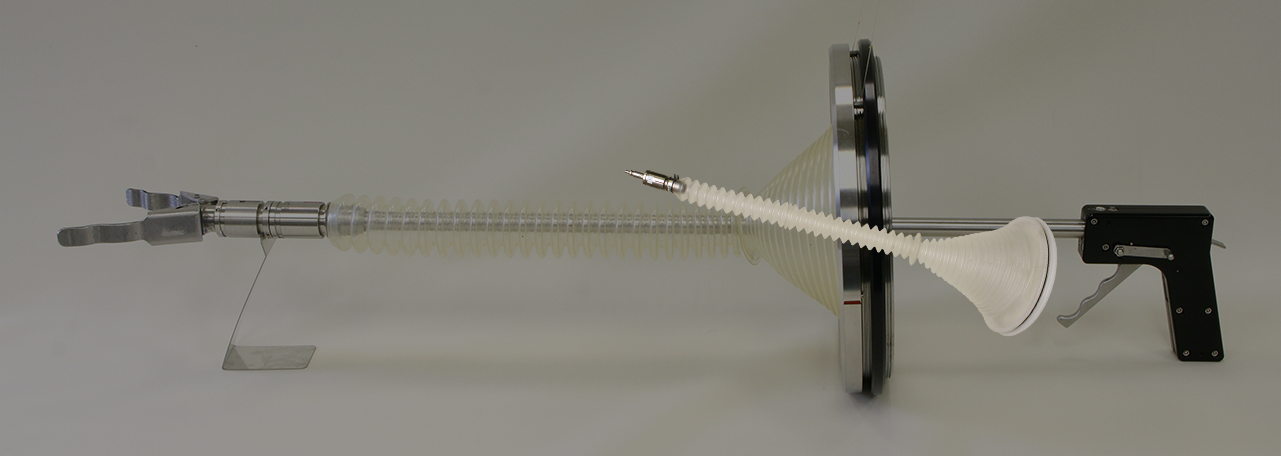

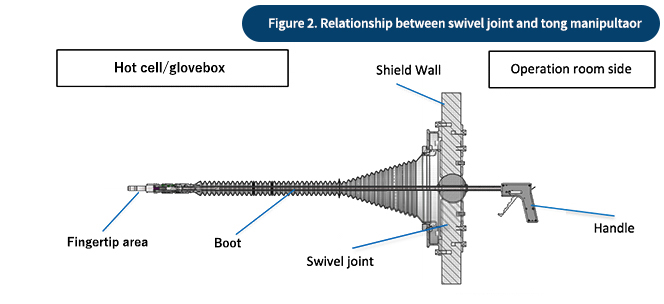

Tong manipulators are used in facilities such as nuclear power research institutes and nuclear fuel offices as shown below.

They are installed for the purpose of handling dangerous substances, such as radioactive materials, in hot cell facilities that handle radioactive materials.

The inside of the hot cell is a space that handles radioactive material, and the operator uses the tong manipulator from the outside of a shielding wall.

The tong manipulator is mounted to a swivel joint to enable a conical range of operation to the front and to the rear.

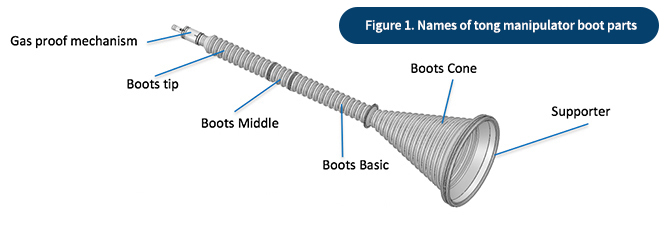

A gap is necessary in the swivel joint section, and to maintain the airtightness of this gap, it is a structure in which a boot is used for sealing this space. Due to our proprietary design and manufacturing methods, our bellows-style conical boots are flexible and durable while maintaining compatibility with conventional boots.

(Patented)

External view

Characteristics

| Compatibility comparison table with conventional boots | ||

|---|---|---|

| Models manufactured by RK Company | TK model | TK component structure of company |

| SV33-25 | TKBA33-25 | Boot, tip |

| SV33-30 | TKBA33-30 | Boot, tip, 1 center part |

| SV33-35 | TKBA33-35 | Boot, tip, 2 center parts |

| SV33-40 | TKBA33-40 | Boot, tip, 3 center parts |

| SV33-45 | TKBA33-45 | Boot, tip, 4 center parts |

| SV33-50 | TKBA33-50 | Boot, tip, 5 center parts |

| Boot | Vinyl chloride specifications: thickness: 1 mm; color: transparent | |

| Airtight adapter coupling area | Support ring connected with O ring and hose band Prevent O-ring detachment in connection with boot |

|

| Supporter | Polyethylene specifications | |

| Enclosure ring | The basic dimensions are the same as those made by RK Company (it can be used for conventional hot cells) |

|

| Air tightness | |

|---|---|

| Air tightness test | Without leakage: pressurized 0.01 MPa, underwater leak test |

| Material strength | |

|---|---|

| Vinyl chloride specification | |

| Under general circumstances | Tensile elongation test (200% or more), tensile strength test (4N / mm 2), hardness JIS K 6253 (55 to 65) |

| Strength after γ ray irradiation(1Mrad irradiation) | Tensile elongation test (200% or more),tensile strength test (4N / mm 2), hardness JIS K 6253 (55 to 65) |

| Polyethylene specification | |

| Under general circumstances | Tensile elongation test (100% or more), tensile strength test (7N / mm 2), hardness JIS K 6253 (90 to 100) |

| Strength after γ ray irradiation(1Mrad irradiation) | Tensile elongation test (100% or more), tensile strength test (7N / mm 2), hardness JIS K 6253 (90 to 100) |

| Ambient temperature and humidity | |

|---|---|

| Ambient temperature and humidity | -5℃ to 60 ℃, 90% or less |

*Please understand that specifications are subject to change without notice due to improvements, etc.

Main applications

Related plants: nuclear power related laboratories (nuclear reactor material, nuclear fuel, structural materials, waste, medical application materials), nuclear fuel recovery business, nuclear fuel manufacturing business, Medical RI manufacturing business, Agriculture related RI manufacturing business